Why does it cost less when you order more t-shirts you may ask? The reason is due to all of the set up involved in printing a shirt. The set up for printing 1 shirt requires all the same materials and time that printing a run of 100 shirts does. So if you are only printing 1 shirt, the cost of all this set up needs to be covered and makes this shirt more expensive than if the costs were being spread over 100 shirts.

For every job, whether it is 1 t-shirt or 100, we do the following set up before we even start printing:

Artwork – Using artwork that will provide a quality screen print almost always requires some work from our graphics guy. Even when customers provide artwork in proper format he still needs to get into illustrator and tweak the image to ensure the best print possible. This image is then printed onto a transparency sheet and is ready for the next step.

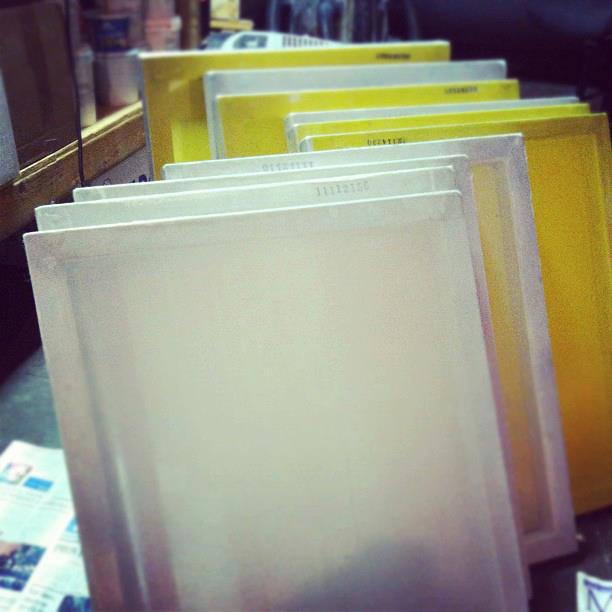

Screen Preparation – Each screen we use, we first need to pre-coat with a liquid called emulsion that is UV light sensitive. It needs to dry completely in the dark room before it is ready for use – usually overnight. We take the transparency with the artwork and place it onto the coated screen. We then expose it to UV light for 3-4 minutes. Then we take it to our wash out booth and use a pressure washer to clear out the image and we are left with a stencil of the artwork. The screen needs to dry and the edges need to be taped and then we are ready to go to press!

Press – Once the screen is ready to go, it can be set up on the press. We first need to ensure the pallets are in the correct position for the specific job we are about to do. We have 4 pallets on our press, and for a big job we will use all of them. Once the pallets are placed, we need to line up the screens. If there are multiple screens (multiple colour print) this also includes registration. Registration is lining up each screen to ensure each colour in the print ends up on the shirt where it is supposed to and that there is no overlapping. Once the set up of the press is done, we’re almost ready to start printing!

Ink – For some jobs it’s as simple as giving the ink a good stir and getting started. However, for some other jobs it requires mixing to lighten, darken or create a new colour. When the ink is ready, we spread it onto the screen and grab a squeegee and GO!